Proper Wire Rope Clamp Installation

Line up your markings and apply the first clip to the assembly.

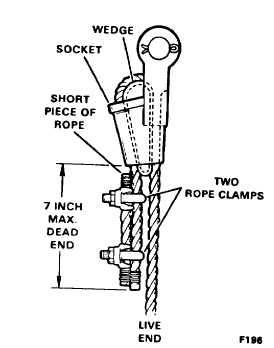

Proper wire rope clamp installation. This load should be of equal or greater weight than loads expected in use. Repeat the process of preparing and attaching the wire rope clamp for the second and third clamps. Install nuts firmly but do not yet tighten to proper torque. Next check and retighten nuts to recommended torque see table 1 this page.

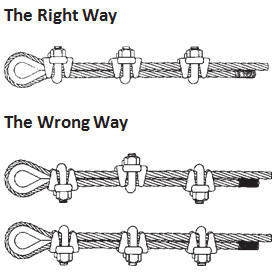

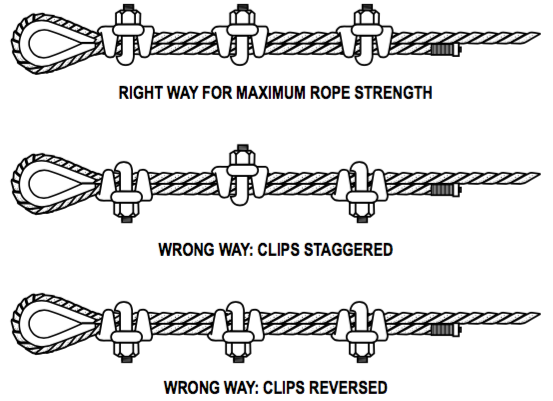

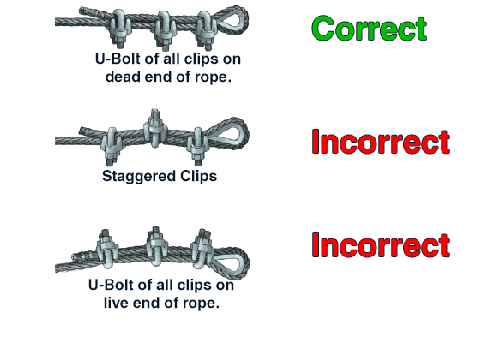

Incorrect installation can reduce the working load limit by 40. Space will be determined by your project the size of the clamps and the rope. Match the same size clip to the same size wire rope. Below are general guidelines for installing wire rope clips.

Apply first load to test the assembly. It means to never apply the saddle of the clip to the dead end of the rope. Incorrect installation can reduce the working load limit by 40 or more. Parts of a wire rope clip assembly clip installation diagram.

Apply first clip one base width from dead end of rope. Below is a diagram showing proper clip installation it is imperative that you install the saddle on the live end of the wire rope. Do not use with plastic coated wire rope. Proper secure of wire rope clip the distance d between wire rope clip and the distance of wire rope clip to tail have to be at least 1 5 times and not more than 3 times of the wire rope clip base width.

Collar nut shall be secured with proper torque value according to size of the wire rope clip to prevent crushing the wire rope if the torque value is too large or wire rope slip over uf the torque value is below the proper or recommended collar nut pre load value. Most clamps come with suggested placement on the packaging. Apply light tension to wire rope assembly to take up rope slack and then tighten all nuts evenly to proper torque. Applying wire rope clips never saddle a dead horse is a common phrase to help people remember the proper orientation to apply the clip.

The easiest thing is to remember never saddle a dead horse the saddle of the clip is the piece that the u bolt fits into. Once the first clamp is attached measure out an appropriate amount of space for the next one. They should be tightened before the rope is placed under tension. Prepare wire rope end termination only as instructed.

The following is based on the use of proper size u bolt clips on new rope. Turnback dead end live end it is important to ensure wire rope clips are installed properly. After the load is placed on the rope tighten the clips again to take care of any lessening in rope diameter caused by tension of the load. Proper usage of wire rope clips clips are usually spaced about six wire rope diameters apart to give adequate holding power.

For situations where use of wire rope clips are approved it s important to remember the proper way to install the clips. We demonstrate the processes.